- Nut-Screw Feeder

- +90 (224) 443 51 77

- nsfeeder@nsfeeder.com

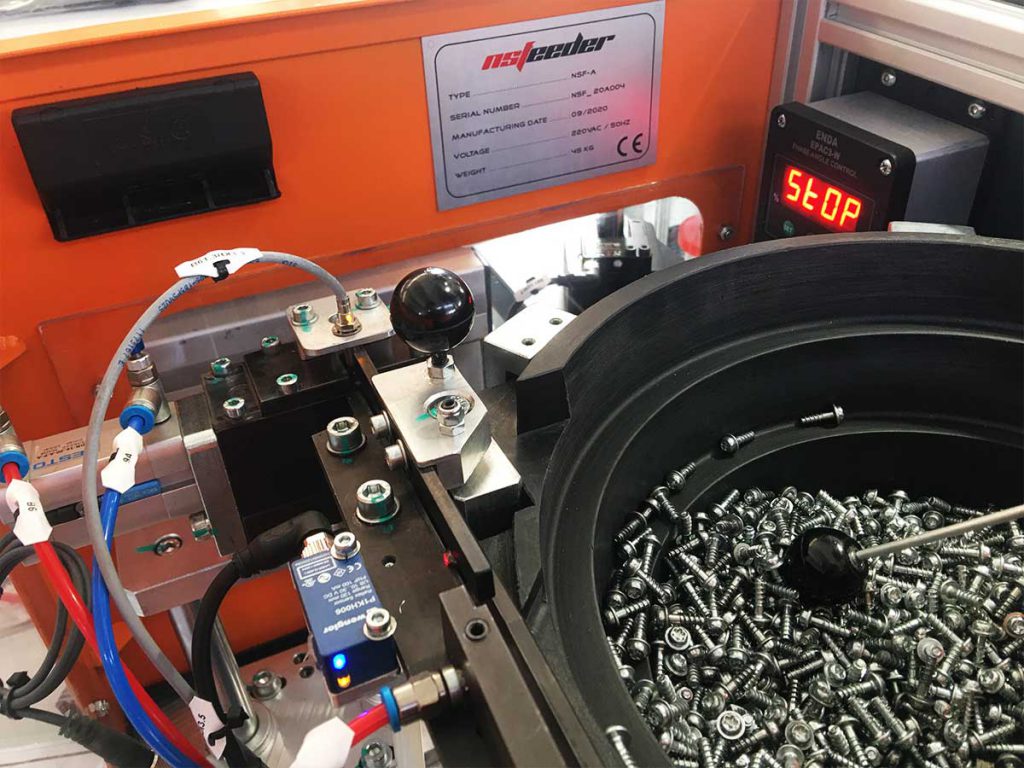

Advantages of screw feeding unit

10 April 2023Screw feeders are used in a wide variety of industries, assembly processes and manufacturing areas. They are particularly useful where precise control of the material flow is required because they can be adjusted to deliver a consistent and correct amount of material to the next process.

The main purpose of a screw feeder unit is to automate the process of screw feeding, which can save time and increase efficiency in the production process. By using a screw feeder unit, operators can avoid having to manually handle screws, which can be time-consuming and labor-intensive.

Screw feeder units typically consist of a hopper that holds the screws, a conveyor or feed tube or chanal that moves the screws from the hopper to the production line, and a control system that regulates the speed and flow of screws to ensure consistent feeding.

Overall, a screw feeder unit helps increase productivity, reduce labor costs, and improve the quality and consistency of the finished product. For an application example, you can visit our https://twitter.com/Ns_feeder page